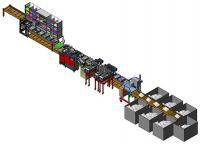

The RCS intermittent, horizontal cartoner from MGS Machine is designed to erect and fill cartons with a range of different products. Large magazines allow for almost continuous operational without the need for reloading.

Features

- 8' x 4' base machine footprint is among the smallest in the industry.

- Modular design handles carton setup and manual load, semi and fully automatic loading applications at up to 60 cpm on the same low cost machinery platform.

- MGS pre-engineered cartoning infeed systems can accept and orient incoming products at speeds in excess of 300 ppm to fully automate the cartoning process.

- Positive vacuum feed carton setup assembly insures positive carton setups every time.

- Servo-driven indexing motion carton conveyor system is easy to access and maintain, uses fewer parts, reduces maintenance requirements and provides accuracy and precise machine movement.

- Heavy-duty welded frame and ball bearings on all drive shafts provides reliability and ruggedness for 24/7 performance requirements.

- Screw adjustable carton width and depth adjustments, and the addition of digital readouts, scales and pointers, support quick, repeatable product changeovers.

- Operator interface is simple to operate.

- Guarding package provides easy access and to enhance vision lines throughout the entire machine.

- Construction fully supports ANSI/PMMI B155.1-2011 safeguarding and cGMP guidelines.

Applications

- Blister Cards

- Kit Packaging

- Software

- Tubes

Specifications

- Output: Up to 60 CPM

- Power: 230/460 VAC, 3 Phase (with disconnect), 60 Hz

- Air: 15-25 SCFM @ 80 PSI, depending on application

Share this product with your colleagues on Facebook, Twitter, Linked in or any other social media website. Click one of the icons below, or join our Facebook page by clicking on the 'like' button at the bottom of the page.